How we work

Reliable absolute quality solutionsThe Fonderia Cunio has been active in the Brescia area for over 20 years in the metal pieces sealing or plastic pieces when they prove to be porous.

Sealing is used to solve all the problems that can be created after the melting process from the micro-porosity of both the raw material and the wrought material. Sealing is used to guarantee the best pressure-tightness without changing the dimension and surface features.

This economical and reliable solution allows for compliance with the most demanding technical specifications.

We perform two different sealing processes and our production capacity is over 2.500.000 pieces/year.

Hot methacrylate

Hot sealing

The increasing demand by the Automotive sector pushed Fonderia Cunio to develop strong strategic partnerships, becoming a leader in the sealing sector using methacrylate resin.

Thanks to the use of efficient machines and the right resins, as well as competent staff, our production is approved in all the main industrial sectors (automotive, aviation, gas, plumbing, agrifood sector, ecc.)

U.V. Controls

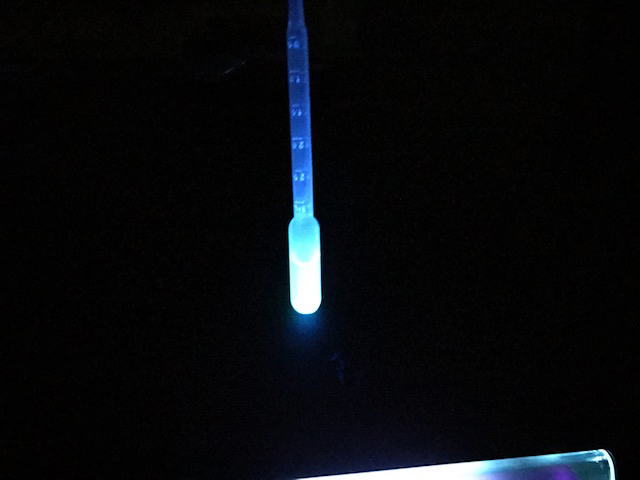

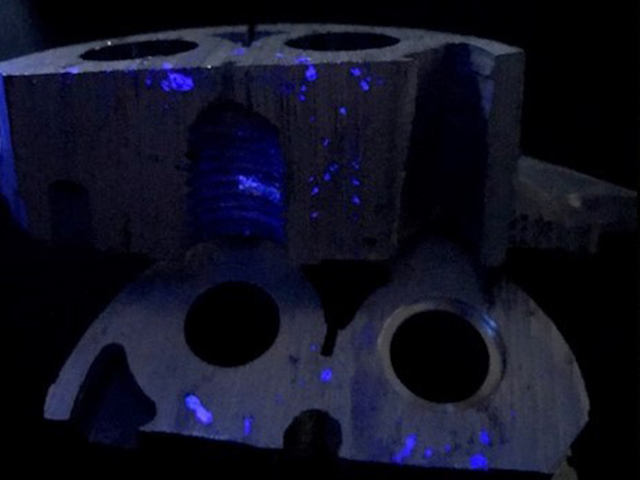

Ultraviolet controlsThe impregnation check, conducted on a sample basis since it is a destructive test,

involves breaking the piece in the area where the leak has been identified and exposing the part to polymerized light.

This process highlights the resin that has penetrated the porosity

Density controlled sintered aluminum samples can be used

that, once broken, allow you to check the penetration of the resin in the various layers.

Imprex® Munari

Treatment against the micro-porosity of the metalsWe use IMPREX® technology for sealing treatments.

It is a resin that penetrates into the porosity of the material that needs to be treated.

After a chemical reaction, it turns into an elastic product that cannot be dissolved in water or other solutions.

The product reacts with acidic substances and becomes immiscible with organic solvents.

Storage and preservation must be done in containers made from materials other than copper, aluminum, steel, tin, lead, or their alloys.

Producer website

3 Porosity Classes

Nature and Extent of the DefectInternal Porosities

These have no significant consequence but are likely to become a bypass during processing.

Superficial Porosities

These can cause visual defects such as oozing, oxidation, or degassing.

Bypass Porosities

Among the most serious, as they allow the infiltration of liquids and gases.

The external appearance of porosities does not allow for determining the nature and severity of the defect. Sealing is recommended after the production process is complete, but before surface treatment, to prevent possible pickling penetration.

Applications

Some Examples of Use

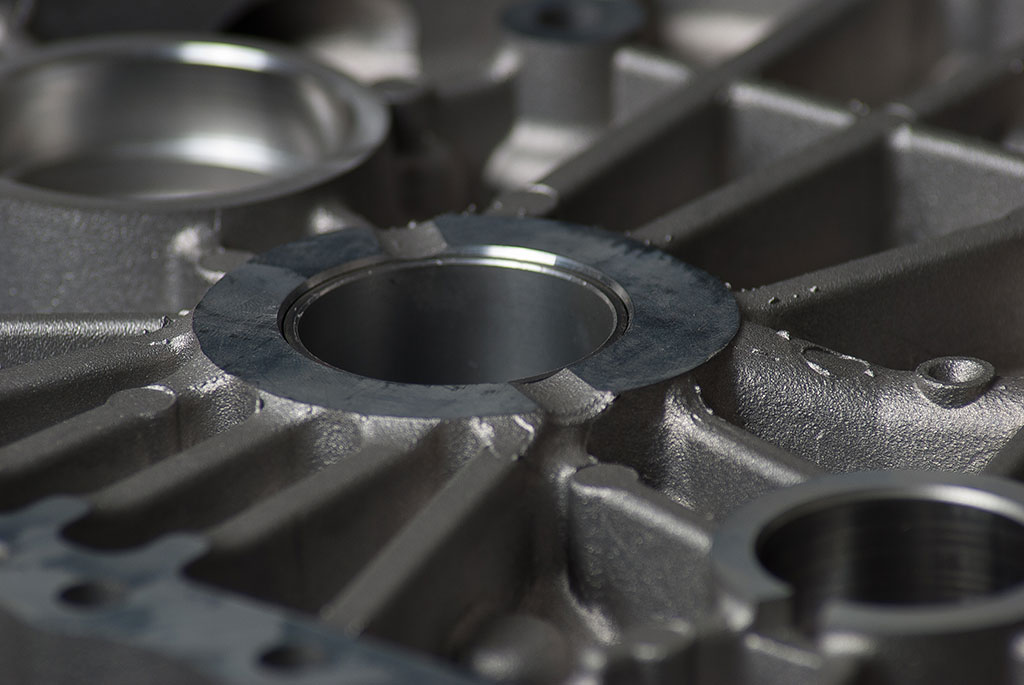

The porous material sealing treatment is performed to decrease permeability and enhance mechanical resistance.

The process used by Fonderia Cunio penetrates the microporosity and adheres to the inside.

After a chemical reaction, it turns into an elastic product that cannot be dissolved in water or other solutions such as hydraulic fluids, antifreeze, motor oils, petrochemical products, brine, water, steam, etc.

After the sealing process, the product can be finished without any risk of compromising the sealing quality.

Here are some examples of applications:

- Oil-hydraulic pumps and water pumps.

- Taps and fittings

- Gas valves

- Actuators

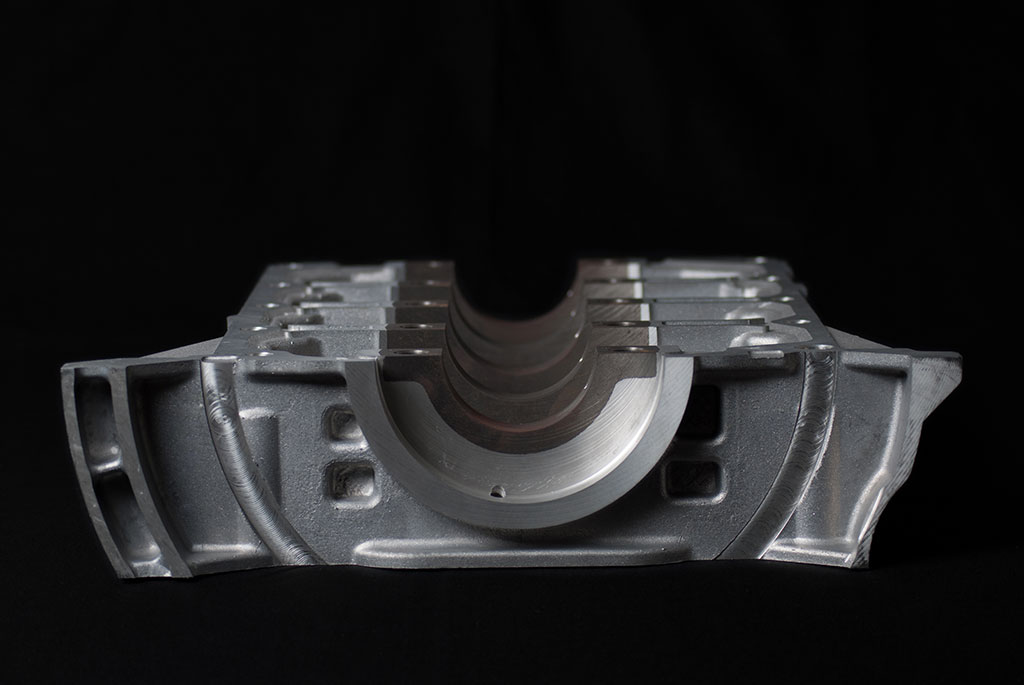

- Cylinder heads and engine blocks

- Aluminum radiators